For a while I had been considering upgrading the front brakes on our car. To be honest, it never felt under-braked but brake fade could be induced at track-days. Typically a Caterham is slightly over-braked at the rear, so I was happy to leave these as they were for now, and perhaps play with brake pads at a later date. There are 2 main options when upgrading the front brakes. The obvious way is to order the AP Racing brakes direct from Caterham Cars. This consists of a set of 4-pot callipers and 2 vented discs (along with associated brake pipes and pads) It is a tried and tested solution but it isn't cheap (about £650), and to be honest the thing that put me off most was the vented brake discs that this package uses. I have seen a few of these crack (although I don't think these are known to crack) but it is the replacement cost of about £120 per disc that puts me off most! An alternative is available from James Whiting, a long established family run workshop and accessory supplier for the Caterham market, who also brought us the Fireblade powered cars. From their website: James Whiting Sevens commissioned Alcon Components Ltd to manufacture 4 piston alloy race callipers to fit onto the standard upright and use the original disc without the need to modify front cycle wing stays. The piston sizes have been specifically chosen to ensure that brake ‘Bite’ is improved and minimal extra pedal travel with the standard 0.7 master cylinder, hence there is no need to fit the 0.812 race spec. Version. Piston sizes are 38.1mm and 34.9mm, as opposed to 41.3mm and 38.1mm for the AP Caliper. The pad area has been increased by approximately 100% over the standard fitment, which reduces the temperature and lowers the risk of the pads ‘going off’. EBC Green Stuff material has been chosen for the kit after extensive testing and provides good all round performance for road and track. However, other grades are available if required. The Alcon Brake Kit was well and truly tested in 1999 when it was fitted to two Caterham Vauxhall race cars that competed in the A.D.A.C. 24 hour endurance race at the infamous Nurburgring Nordscleiffe circuit. The cars were entered by Prosportif Ltd and finished 8th & 13th in class, 52nd & 83rd overall from 195 entrants. Both cars completed the race using ONE set of Pagit brake pads each. Good enough for me!! The added bonus is that the kit retails at about £500, and uses the standard original solid brake disc - these cost about £10 each!!

One of the biggest advantages of using the Alcon system over the more expensive AP solution is the use of standard sized solid discs - at about £12 each they are considerably cheaper than the ventilated discs that the other systems use. This is great when changing pad type - some of the more expensive/exotic pads suggest that you change to new discs at the same time as fitting them.

|

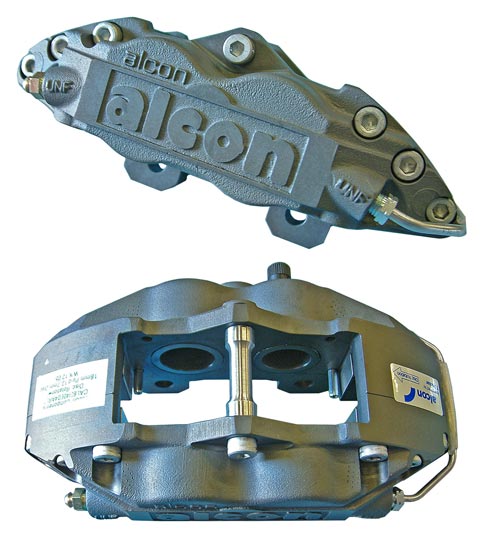

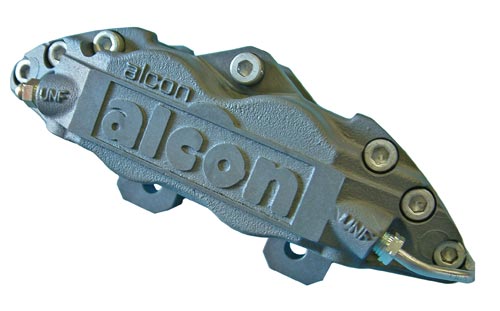

Nice shiny new alloy caliper (some packaging removed!) This is one of those parts that is great to put on your car - they look and feel great (if one is into this sort of thing!!)

Nice shiny new alloy caliper (some packaging removed!) This is one of those parts that is great to put on your car - they look and feel great (if one is into this sort of thing!!)

Until you take one of the old calipers off your car you will have no idea how heavy they are!! Despite the size the new ones are much lighter!

Until you take one of the old calipers off your car you will have no idea how heavy they are!! Despite the size the new ones are much lighter! This shows the difference between the new and old brake pad surface area. You can see why heat becomes less of an issue with the increase....

This shows the difference between the new and old brake pad surface area. You can see why heat becomes less of an issue with the increase.... As we have flared wings on our car James provided us with 2 options for the braided brake pipes, to ensure that there was no interference issues between wheels and side skins - our car has a greater lock than those with cycle wings.

As we have flared wings on our car James provided us with 2 options for the braided brake pipes, to ensure that there was no interference issues between wheels and side skins - our car has a greater lock than those with cycle wings.

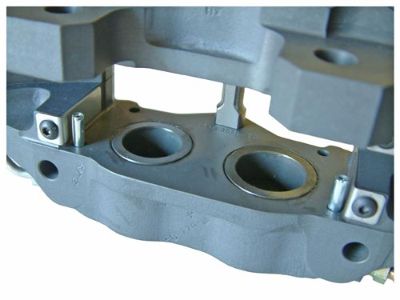

You can see the different sized pistons in the calipers - the larger is at the leading edge of the pad, so ensuring that the pad is pressed well onto the disc, and sort of 'rolls' against it.

You can see the different sized pistons in the calipers - the larger is at the leading edge of the pad, so ensuring that the pad is pressed well onto the disc, and sort of 'rolls' against it. Re-fitting the wheel bearings after fixing the new discs.

Re-fitting the wheel bearings after fixing the new discs. New caliper in position. At the time of fitting James supplied the Alcon pads with 'Greenstuff' brake pads. I think these may have subsequently been replaced with a different pad now...

New caliper in position. At the time of fitting James supplied the Alcon pads with 'Greenstuff' brake pads. I think these may have subsequently been replaced with a different pad now...

Shame you can't see them so well when the wheel is fitted!!

Shame you can't see them so well when the wheel is fitted!!

At the same time as fitting the new Alcon brakes we decided to replace the old rear discs, which were getting quite worn.

At the same time as fitting the new Alcon brakes we decided to replace the old rear discs, which were getting quite worn. Disc and hub removed

Disc and hub removed  By comparing the swept surface of the outside of the disc with the inside surface (see 2nd picture below) you can see how the pads were being used unevenly.

By comparing the swept surface of the outside of the disc with the inside surface (see 2nd picture below) you can see how the pads were being used unevenly.

A needle file was used to clear off the flaky rust and expose the bolts that held the discs to the wheel hub.

A needle file was used to clear off the flaky rust and expose the bolts that held the discs to the wheel hub. Tessa lends a hand.

Tessa lends a hand. Some of the more stubborn bolts did not respond to the impact wrench - so more drastic measures were required!

Some of the more stubborn bolts did not respond to the impact wrench - so more drastic measures were required! Obviously we would not be re-using these bolts!

Obviously we would not be re-using these bolts! Nice new shiny rear disc fitted and awaiting caliper and pads.

Nice new shiny rear disc fitted and awaiting caliper and pads.

Refitting the caliper.

Refitting the caliper. Barney looking suitably impressed as usual!

Barney looking suitably impressed as usual!